E-Recycling Services

Our Process for Recycling Electronics

Our electronics recycling process is made up of a sophisticated process of shredding and product destruction, done in a way that offers you and your business complete privacy and protection. Because of our state-of-the-art recycling model that uses multiple sortation technologies, Adams Cable Equipment is capable of segregating the various types of ferrous, non-ferrous, plastic, and precious metal components from recycled electronics. This enables us to follow strict e-recycling protocols and fully participate in electronic scrap recycling — only after all private, personal, and identifiable data is first completely destroyed. Our industrial-grade shredder is capable of shredding all types of storage devices and eliminating information, so your company’s privacy and protection are assured.

Here’s a look at each step of the process, and why it’s important:

Shredding:

This effectively destroys all existing data in computers, cell phones, tablets and other devices. In the case of commercial electronics recycling, this typically involves the destruction of proprietary data that’s crucial to the operation of governments, corporations, companies and small businesses. At Adams Cable Equipment, we use an industrial-grade shredder to ensure that data is completely eliminated. The complete and thorough destruction of proprietary data is one of the most important reasons why businesses should use a commercial electronics recycling company.

Electronics destruction:

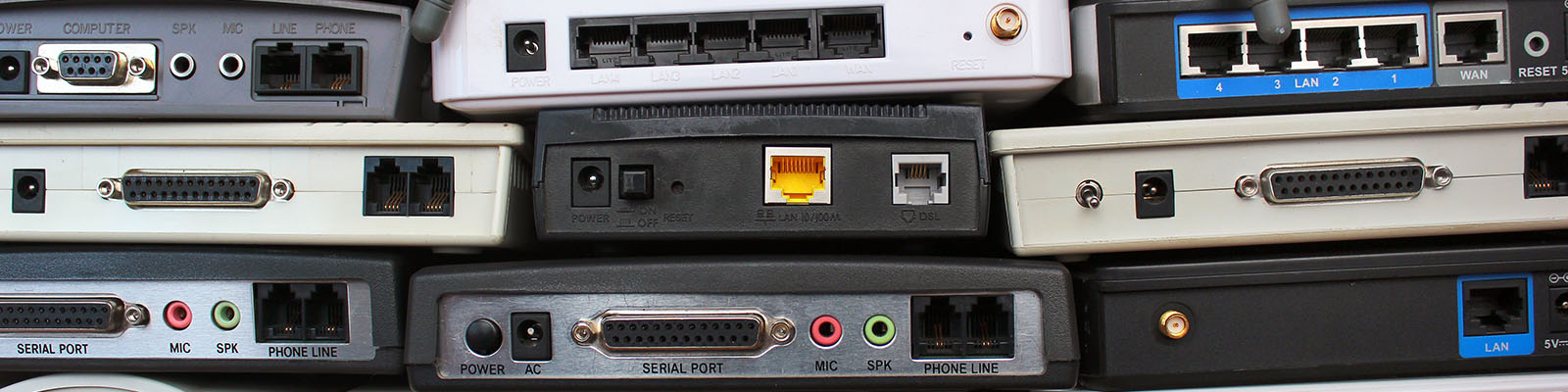

In this step, the electronics device is completely disassembled, part by part. In the dismantling process, electronic waste that cannot be recycled is separated from reusable components and disposed of properly. Reusable components are removed and sent to be sorted and separated.

Sorting and separating:

During this process, all reusable components are separated into different categories. These include recyclable components and materials such as metal, glass and plastic. In addition, e-recycling yields a wealth of precious metals like gold, silver, platinum and palladium, which are sent to smelters and refineries so they can be refined to their maximum metal purity.

Recycling:

This step involves the selling and distribution of all reusable components and materials. Typically, many of these materials are sold to electronics manufacturers so they can be used to build new electronic products. However, in many cases, components such as precious metals are also sold to other industries, including jewelry manufacturers. Everything that can possibly be recycled is removed and sold to these various industries.

Safety and Compliance Protocols

As a leader in commercial e-recycling services, Adams Cable Equipment is proudly committed to following the highest safety and compliance protocols. Our entire process, from start to finish, is fully certified and audited in conformance with industry regulations set forth by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC). Our ISO/IEC compliance ensures that you can expect the highest level of service and safety practices from our team.

In addition, we follow a strict Quality, Environmental, Health and Safety (QEHS) management system, with established company protocols for reuse, refurbishment, recovery, and disposal of all the materials we handle. This ensures that we’ll provide the highest quality recycling services to our clients.

READ OUR NEWS AND UPDATES

Read our Kick ACE blog to stay up to date on the latest from Adams Cable Equipment! We share industry news, product expertise, and company updates to keep you informed.